In the ever-evolving world of construction and civil engineering, precision and efficiency are critical. Modern projects demand tools that can handle complex designs, ensure safety, and streamline workflows. That’s where Structural Analysis Engineering Software steps in as a game changer.

What Is Structural Analysis Engineering Software?

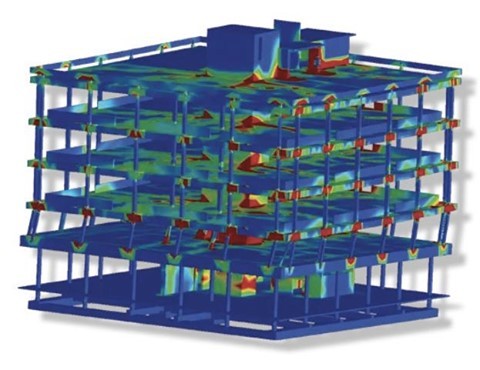

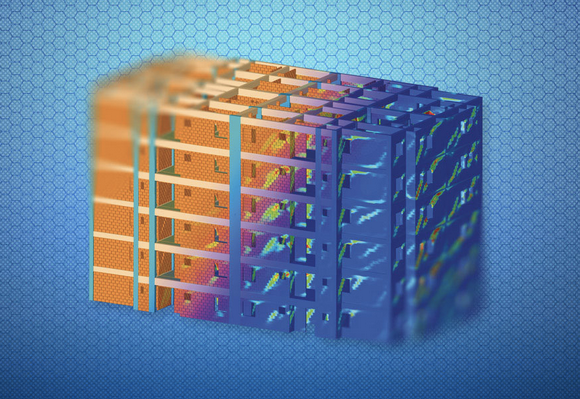

Structural Analysis Engineering Software is a digital tool used by engineers to evaluate the structural integrity of buildings, bridges, and other infrastructures. It simulates real-world forces such as loads, vibrations, and environmental conditions, helping engineers predict how structures will behave before they’re built. By using this software, professionals can detect weak points, ensure code compliance, and avoid costly design errors.

Key Features and Benefits

One of the most significant advantages of Structural Analysis Engineering Software is its ability to conduct detailed simulations. From analyzing stress distribution in steel frames to evaluating seismic responses, the software provides comprehensive insights that manual calculations simply can’t match.

Other key features include:

- 3D Modeling and Visualization: Create detailed models that represent the actual structure with precision.

- Load and Stress Analysis: Evaluate how structures respond to different forces, including wind, snow, and earthquakes.

- Material Behavior Simulation: Understand how various construction materials will perform under different conditions.

- Code Compliance Checking: Ensure your design meets regional and international standards.

Who Uses This Software?

Structural Analysis Engineering Software is used by civil and structural engineers, architects, contractors, and infrastructure consultants. Whether it’s a small residential building or a massive suspension bridge, this software helps in making data-driven decisions throughout the design and construction process.

Why It Matters Today

In today’s fast-paced construction environment, mistakes can lead to significant delays and financial losses. More importantly, structural failures can pose serious safety risks. By using advanced Structural Analysis Engineering Software, professionals can optimize their designs, reduce waste, and improve safety outcomes.

Final Thoughts

As technology continues to transform the construction industry, Structural Analysis Engineering Software remains a cornerstone of innovation. It empowers engineers to build smarter, safer, and more sustainable structures. Whether you’re designing a skyscraper or a footbridge, investing in the right software could be the key to your project’s success.